Why Turnkey Contracting of your Stone Work Unit?

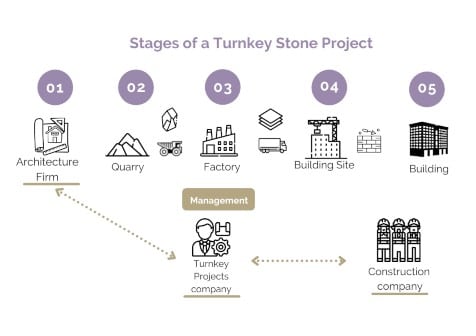

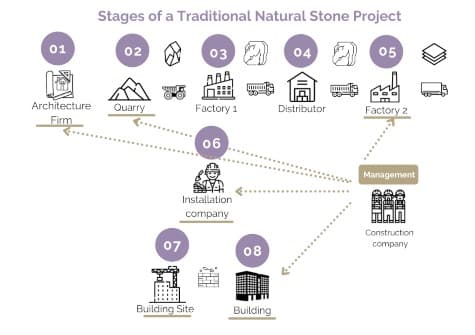

More and more clients are opting for turnkey solutions to contract any service. Nevertheless, in construction projects with natural stone, this type of contracting is not so common.

In this post we are going to explain all the advantages of contracting turnkey projects, specifically for stone work units.

It is clear that many of these advantages are common to the general turnkey concept, which in brief are:

- Relying on a single company and therefore on a single interlocutor, thus avoiding the inconvenience of having to manage a large number of unconnected suppliers.

- More agile and efficient project control from start to finish

- Increased guarantee of compliance with delivery deadlines

- Responsibility rests with a single company “the subcontractor”.

- Agreed and fixed price at the beginning of the project, thus avoiding unpleasant surprises.

1. Factors to consider in a turnkey project with natural stone

These are some of the particular aspects to take into account when working with a natural material such as stone:

1.1 Number of references and origin of materials:

Natural stone has an infinite number of commercial references for the same material and these, in turn, can come from any part of the world.

Italy, Greece, Turkey, China, India and Brazil, together with Spain, are the world’s largest producers and exporters of natural stone, but they are not the only ones. More and more new materials are being added to the “reference list”. Countries such as Egypt, Oman, Nigeria, Saudi Arabia, Morocco, Algeria and even Angola are opening up a niche in the market with very interesting materials at very attractive prices.

1.2 Atomisation of the Stone Sector:

The stone sector in Spain is mainly made up of small companies that are generally highly specialized in activities such as:

- Extraction

- Slabs and tiles manufacturing

- Handicraft

This specialization makes these companies tremendously attractive thanks to their excellent quality work, although most of them are limited to integrate all the activities required for a turnkey project.

1.3 Characteristics of the extraction area (quarry)

The physical-mechanical parameters of the same commercial reference can vary from one quarry to another, and even from one extraction area to another within the same quarry. We cannot lose sight of the fact that we are dealing with a natural material. Hence the importance of knowing in depth the specific area of origin and determining in detail, if necessary, its physical-mechanical parameters by carrying out the appropriate laboratory tests for each case.

1.4 Formats and finishes of the stone:

The shape, size and thickness -among others- of the type of stone to be chosen will depend directly on the characteristics of the construction project (building design) together with others such as the location of the installation, the climate and other external environmental aspects, type of fixing to be used, etc… and of course the characteristics of the material itself.

Determining them in detail through the use of engineering calculation models will help to save costs and time.

1.5 Intrinsic “natural” characteristic of the stone:

This will have a direct influence on its behaviour not only during manufacture, but also with regard to the different fixing elements and the installation itself from a chemical, physical and mechanical point of view.

For all these reasons, the most advisable is to have expert installers who know the characteristics and properties of each material and, of course, of the specific project.

2. Recommended areas of expertise in a subcontracting company for turnkey stone projects

2.1 Geology

Utility: To locate the best suitable quarries and/or extraction areas for materials.

In other words, the most advisable it’s to have experts who know how to identify the stresses to which the rock masses from which the stone is extracted has been subjected, as this will influence the behaviour of the stone over time.

It should also be borne in mind that the simple progress of the extraction of the material in the quarry means that the resistance of the materials may vary. On the other hand, depending on the physical-chemical characteristics of the material, the use of different surface treatments will be recommended.

2.2 Engineering/Architecture:

Use: To create models that characterise the stone “like a synthetic material” and to carry out the necessary technical checks according to the ELU (Ultimate Limit State) and ELS (Service Limit State) methods.

The location of the construction site implies wind loads and seismic loads specific to each building, which must be taken into account. It will also be necessary to consider environmental aspects such as climatology, since, for example, humidity and/or temperature have an important influence on the alterability of materials, as well as contamination, among others.

2.3 International Trade:

Usefulness: This will be of particular relevance for medium to large projects, where an imported material has been prescribed..

The expertise of the sales team in locating the most suitable quarry, both in terms of quality and price, will help to considerably reduce the project budget, as raw material costs can be almost half of the total budget.

Going directly to the quarry to purchase the material will result in considerable savings in project costs.

2.4 Construction/Installation/Fixing systems:

Utility: All of the above factors can be affected by incorrect installation.

Therefore, it is essential to have experts in the sector who can not only carry out the installation, but also guide architects and builders at the beginning of the project on the most suitable ways of installation.

In other words, having support during the conceptual phase of the project, with practically the last agents involved in the project (360º stone expert), can be very advantageous economically, in terms of deadlines and, of course, when it comes to obtaining the best possible result..

2.5 Project management:

Usefulness: A proper “Project Management” means that all the actors involved in the project – whether at national or international level – speak the same language.

Following the methodology of organizations such as PMI (Project Management Institute) is a basis on which to build methodologies, policies, procedures, rules, etc., necessary for the practice of project management.

Workflow of a turnkey stone project

3. Overview of the advantages of contracting a turnkey project with natural stone

The collaboration of natural stone experts with architects and designers will allow to dimension the formats and thicknesses of the stone slabs, as well as the optimal anchoring system.

In addition and based on our experience, we can say that a well-executed turnkey project is the best guarantee to avoid possible pathologies in the future.

Hence, why contract a turnkey natural stone project?

- Because the choice of stone at the earliest stages of the conceptual design, allows the client to optimize his project based on key decisions such as: cladding weight, façade layout, etc.

- Because it allows us to control all phases of the project, enabling quality assurance and control in each of them. A preventive approach thus avoids that material which is not in accordance with all the technical specifications, arriving on site.

- Checking the substrate on which the stone is to be anchored, as well as the execution of the installation, is essential to ensure that there are no faults or breakages.

- Last but not least, by optimizing all phases, we can be more competitive and therefore maintain value for money.

And I don’t want to end this post without remembering the words that stuck with me at one of the first conferences I attended, at the beginning of my professional career in this sector, and which I have always kept in mind since then:

“There are no good or bad stones, but stones used well or badly.”

Fernando López G. Mesones.

We hope that this article has given you some clarification on the route of stone; from the moment you decide to use it until it forms part of the building, and why it is important to leave it in hands of an expert company that controls it from start to finish, i.e. a company that specializes in carrying out integral or turnkey projects.

At Albora we have more than 15 years of experience in carrying out comprehensive projects with natural stone in Spain, Europe and the Middle East

If you think we can be of any help, please do not hesitate to contact us and of course we welcome all your comments.

Note: Cover image: Adnoc Headquarters, Abu Dhabi, UAE. World’s tallest granite façade.

No Comments